4. SPECIAL PROBLEMS

-

a. Large rock or boulders: At this point something should he said about large rocks or boulders-nemesis of the placer sampler.

When sampling placers there is a natural tendency to bypass areas of heavy boulders or, at least, to take the finer material from among them without considering the end effect on indicated values. In many cases the effect is the same as salting the sample, a fact which does not seem to he recognized by some mineral examiners.

Consider that the gold particles or other valuable minerals in placers are found among the finer-size material while on the other hand, the large rocks or boulders contain no recoverable values within themselves. For this reason, when the sampler takes too much fine material or fails to make an allowance for valueless boulders, he is likely to report an incorrect, high value. To put it another way, where all hank-run material including boulders will he handled in a mining operation, the prospecting should reflect this fact by including a proportionate amount of large material in the samples.

A direct approach to sampling the type of ground under consideration would he to cut samples large enough to include the fair proportion of large-size rock and thus obtain samples which truly represent the mine-run material, boulders and all. But where the mineral examiner must work alone or where a limit is placed on the size of his samples through the use of hand tools or for other reasons, the taking of very large samples may not he practicable. In such cases, he must settle for something less than optimum size, hut he can guard against possible error in his end valuation by first carefully evaluating the problem and, second, adjusting his calculated sample values (if necessary) to correspond with those which might be obtained from a suitably large-size sample.

In practice this can often he achieved by visually estimating the boulder content of a piece of ground and, where needed, inserting a correction factor in the end sample calculations.

Consider a case where it was estimated that 10 percent of the bank-run material was too large to be represented by material taken from a 3" x 6" x 4' channel cut. The 55.9 pounds of material removed from this cut contained 2.70 milligrams of gold. The indicated value based on these weights was 13.3 cents per cubic yard.

Now, to include a proportionate amount of boulder material this particular sample would have to he 10 percent heavier. In other words, it would weigh 55.9 pounds plus 10 percent, or a total of 61.5 pounds. Using this new weight and the same 2.70 milligrams of gold, the calculated bank-run value becomes 12 cents per chick yard.

In practice the same end figure can he obtained by simply reducing the uncorrected value by a percentage factor equal to the estimated boulder content. In other words, 13.3 cents minus 10 percent equals 12 cents per cubic yard, bank-run value. 63

The sample notes and subsequent data sheets must, of course, clearly show all such adjustments and they should preferably show both the uncorrected and corrected figures.

Before leaving this topic it will be pointed out that while the foregoing correction procedure is generally reliable, there are placers having boulder problems so severe, they cannot be effectively sampled by any means short of mining the entire deposit.

-

b. Erratic high values: The usual methods for calculating the value of placer ground rely on an assumption that the value found in a particular sample extends halfway to the next sample. In effect, this assumes that the mineral content changes at a uniform rate between sample points. While valuation procedures based on this concept work well for ground having a general low or uniform average, the finding of erratic high-value samples can create problems. In practice it has been found that to include them at full value will often result in an over-valuation of the lands involved. There are several ways to approach this problem:

First, the sections in which they occur should preferably be resampled. If the resulting value is low, it is safer to use the low figure and this is sometimes done. Where the two results are about the same, most engineers will use the average.

Another commonly used method for adjusting erratic high values is to decide what the highest value reasonably expected from the particular ground might be. This is estimated after considering the type of deposit being dealt with, the overall sample results and in particular the neighboring samples. This might be called the "normal" high value expected in a given property or locality. The erratic "too-high" value is then downgraded to match this figure.

But where it is reasonable to believe that the property as a whole is made valuable by occurrence of erratic, high-value areas, it may be proper to use all sample results at their full value.

There are, of course, other approaches to the problem but in any event the method for handling erratic high values should be governed by conditions found in the particular deposit being investigated. Needless to say, no method of discounting high values should be adopted' until the reason for their occurrence is understood.

5. UNCASED OR SMALL-DIAMETER DRILL HOLES

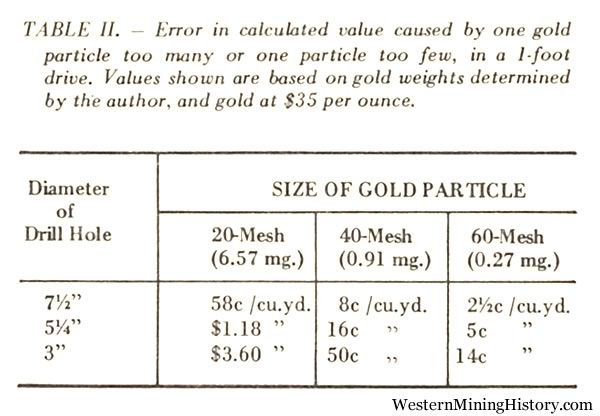

Various attempts to sample gold placers by use of uncased or small-diameter drill holes have for the most part generated more problems than they have solved. As noted earlier, the volumetric gold-to-gravel ratio in 15-cent ground is about one to a hundred million (1: 100,000,000). This tells us that calculated drill hole values are extremely sensitive to stray gold particles or incorrect sample volumes. The effect of one gold particle too many or one particle too few is shown in Table II.

It can be seen that any sloughing of an uncased drill hole, should it occur in a gold-bearing zone, will tend to upgrade the calculated value by significant amounts. If one knew with certainty how much excess material entered a sample and exactly where it came from, the discrepancies might be appraised and allowances made during the calculation process. But experience tells us that this is not always practicable and that when dealing with the usual gold placer. uncased drill holes just do not give reliable results. More often than not the ground will be over-valued and this seems to be particularly true when rotary drills are employed, especially those using roller-type bits. In one case, placer ground reported to run 26 cents per cubic yard on the basis of samples obtained from rotary drill holes was found to contain 1 1/4 cents per cubic yard when checked by an experienced dredging company using a Keystone placer drill and qualified crew.

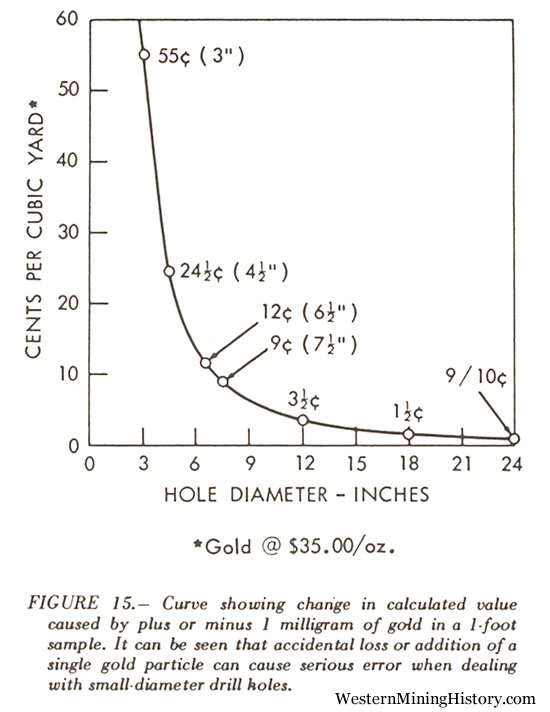

The mineral examiner should always view critically any placer evaluation based on gold values obtained from uncased or small-diameter drill holes. Figure 15 shows why, in the case of small-diameter holes, the indicated values are not always reliable.

While some gold dredging companies occasionally employ 4-inch churn drills for preliminary prospecting, the 6-inch size equipped with a 7 1/2-inch diameter drive shoe is considered standard.

Under certain conditions, small-diameter drill holes may be both practical and adequate. As an example, when evaluating beach-type deposits valuable for their chrome or titanium-bearing minerals it is often possible to rely on small-diameter (say 2-inch) holes for sampling. Here the fine-grained nature of the deposit, the relatively large proportion of valuable mineral and its low unit value combine to eliminate some of the uncertainties normally associated with small-diameter drill holes. As another example, consider a tin placer containing 1/10 lb. cassiterite per cubic yard. With tin at $1.50 per pound, the indicated value would be 11.6 cents per cubic yard and the volumetric ratio of cassiterite to gravel 1: 114,000. In other words, the volume of valuable mineral in this case would be approximately 1,000 times greater than the volume of gold in a comparable gold-placer and this illustrates why low-value placer minerals are, in general, easier to sample.