-

c. Machine-dug shafts: Machine-dug shafts have been found both useful and economic in a number of instances but they are not a cure-all for placer sampling problems. The equipment used can broadly be divided into two types: rotary bucket drills and clamshell-type excavators. To be effective, either type must be capable of doing three things: (1) dig a hole large enough for a man to enter and inspect the ground or to cut samples from the shaft walls; (2) have a reasonably fast digging rate; and (3) be self-contained, freely movile and capable of negotiating rough terrain.

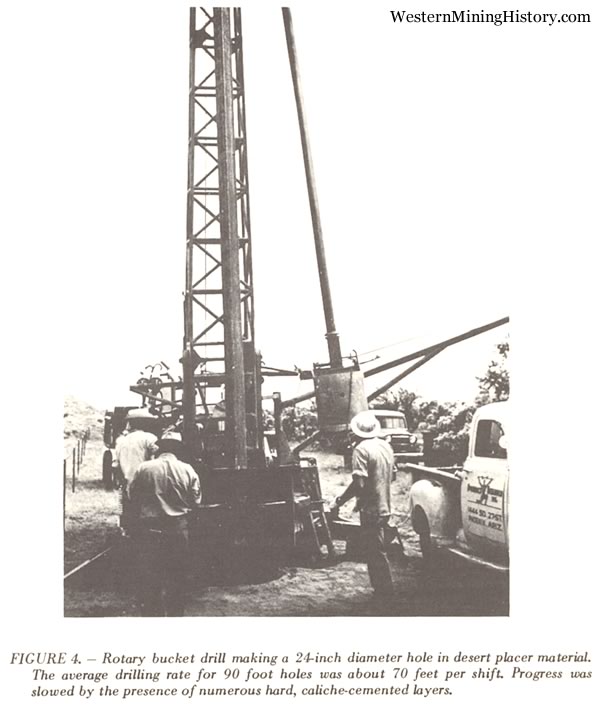

Truck-mounted bucket drills have been in use for many years by excavation contractors, particularly those specializing in foundation test work. Their equipment is usually designed to dig a hole 24 or 36 inches in diameter and to depths of 60 feet or more. The digging unit can best be described as a straight-sided bucket which has two radial openings in its bottom and excavating blades extending below the openings. Rubber flaps fitted over the openings allow cuttings and rocks lo 6-or 8-inch size to pass into the bucket but seal the openings when the loaded bucket is being hoisted. The bucket is rotated by means of a square "Kelly" bar which, in turn, is rotated by a ring gear on the drill rig. See Figure 4.

Attempts to adapt this type of drill to placer sampling have met with mixed success but speaking generally, rotary bucket drills have been found useful where the ground is dry and firm and where there are few rocks too large to pass through the bucket openings. On the other hand, they have been found poorly suited to the hard, rocky ground encountered in many gold placers.

The successful use of rotary bucket drills to sample dry placers has been described in articles by Draper (1932, p. 537) and by Prommel (1937). Prommel describes a sampling project in which 1,239 test holes 28 inches in diameter were drilled in 147 days. Their combined depths amounted to 16,705 feet. The cost of this work using two rotary bucket drills was 98.6 cents per foot of hole but this did not include engineering or sample testing charges and, it should be noted that the low cost reflects depression-level prices of 1935.

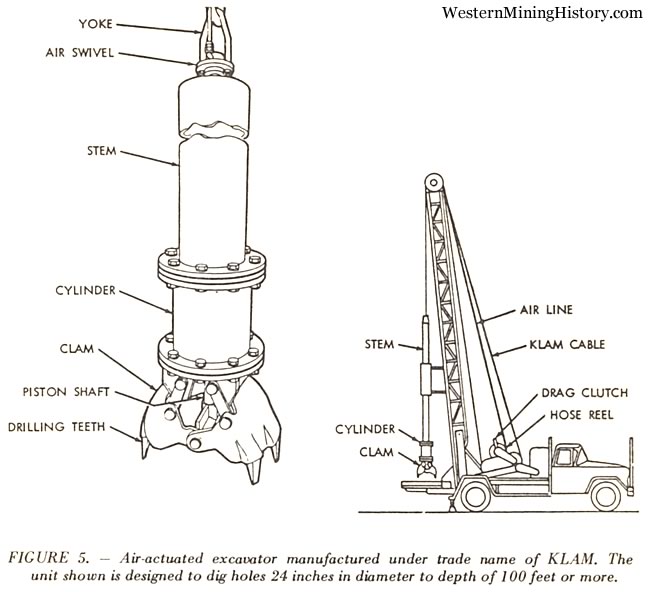

Two clamshell-type machines designed specifically for placer prospecting are: An air-actuated unit sold under the trade name KLAM, and a cable-actuated unit known as the PAR-X Placer Sampler. The KLAM is essentially a manganese steel clamshell bucket of 1 cubic foot capacity, fitted with replaceable teeth and actuated by compressed air. The digging unit consists of the bucket, an air cylinder placed directly above the bucket and a 15-foot stem as shown in Figure 5. The combined digging unit which weighs one ton is suspended from the mast of a drill truck by means of a wire line spooled on a suitable hoist. According to the manufacturer, the standard unit digs a round, vertical hole 24 inches in diameter. and is efficient to a depth of 100 feet. It is said to dig from 2 to 20 feet per hour depending upon depth, formation, and on whether or not casing is used.

The PAR-X machine differs from the KLAM in that the clamshell is attached to a telescoping stem or bucket carrier which limits the depth of hole to about 30 feet. The opening and closing action is controlled by wire ropes. The unit is truck-mounted and, according to Huttl (1941, pp. 55, 56), its digging speed averages 35 feet per day in normal ground. It digs a hole 28 inches square without casing.

Machine-dug shafts are best suited to bulk sampling, that is, sampling in which the entire volume of material removed from the shaft is run as a sample. Where the ground stands well channel samples can be cut from the shaft walls but there is hardly room for a man to work effectively in a 24-inch diameter hole. However, the fact that machine-dug shafts can be entered for inspection is a point in their favor, particularly in new fields where little is known about the sub-surface conditions.

Something proponents of this method of placer sampling seldom mention is the fact that an uncased, machine-dug shaft passing through alternating hard and soft layers or through ravelling ground will have a non-uniform diameter, that is, it may be appreciably larger in the softer horizons than in the hard. This means that where over-diameter shaft sections occur in ground that is above average or below average mineral value, the end result will be an unintentional salting or an impoverishment of the bulk sample.

To cite an actual case, a dry, desert placer was sampled by means of 24-inch diameter machine-dug shafts ranging from 60 to 90 feet deep. Both rotary-bucket and Klam-type excavators were used. The valuable mineral was magnetite occurring in the form of black sand. When the completed shafts were entered for inspection, it was found that the shafts had passed through a series of hard, caliche-cemented gravels separated by relatively loose sand and gravel strata and, in all cases, the shaft diameters were appreciably larger in the softer materials than in the cemented horizons. Sections were found enlarged to as much as 2.5 times the normal 24-inch diameter. If the grade of material throughout the shaft had been uniform this local enlargement would be of no consequence, but it was found that the enlarged sections were often in magnetite-rich sands. As an end result, samples (representing 3D-foot shaft increments) contained too large a proportion of the richer material which in effect amounted to unintentional salting. Had this been a gold prospect the errors caused by non-uniform hole size would have been substantial.