4. PROCEDURE FOR DETERMINING RECOVERABLE GOLD IN PLACER SAMPLES

- a. Reduce the original sample to a black sand concentrate by panning, rocking, or other suitable means.

- b. Place the concentrate in a pan, then count and record the gold colors as #3, #2 or #1 - size (Note 1). At this point, manually remove any gold particles which are to be kept in their natural form (Note 2).

- c. Add a globule of clean, gold-free mercury (about the size of a small bean) and working over a safety pan reduce the black sand to a small-volume concentrate. Near the end of panning process the mercury may tend to ride over the top of fine-size or hard-packing materials but by this time all gold should have been picked up by the mercury.

- d. Remove the mercury and place it in a 250 ml Pyrex beaker. Add 40 or 50 ml diluted nitric acid (Note 3) and digest until the mercury globule is reduced to the size of a match head. Transfer to a #0 glazed porcelain parting cup, add fresh acid and complete the digestion using low heat if necessary. Fine-size gold will be left as a coherent, sponge-like mass if rapid digestion or boiling is avoided.

- e. After decanting off the acid, carefully wash the gold three or more times with warm water. Add a drop or two of alcohol (to prevent spattering) and dry in the parting cup at low heat.

- f. Anneal the gold by bringing the bottom of the parting cup to a low red heat. This step will eliminate any residual mercury and is essential when working with very small gold weights.

-

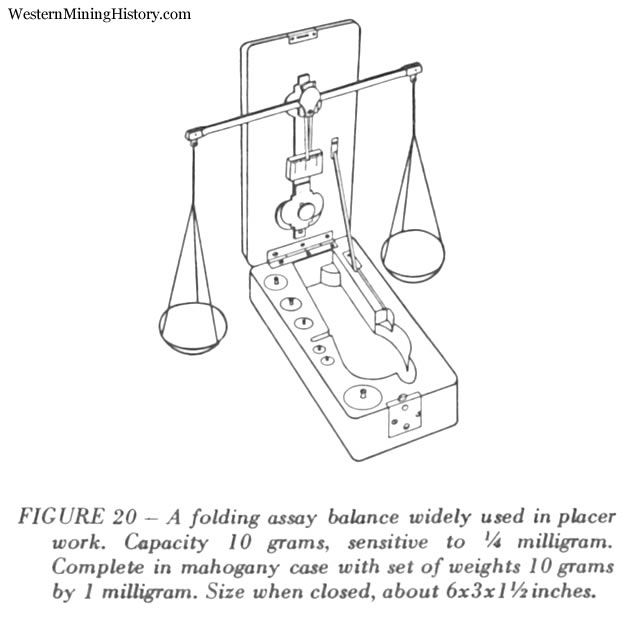

g. Transfer the annealed gold to a balance pan and weigh. A balance widely used by placer engineers is shown in Figure 20.

NOTES

-

1. Number 3 colors consist of gold particles weighing less than 1 milligram.

Number 2 colors weigh between 1 milligram and 4 milligrams. Number 1 colors weigh over 4 milligrams. Gold particles weighing 10 milligrams or more should be individually weighed and recorded. - 2. Placer gold loses its original surface texture when amalgamated. In the case of fine-size gold, its end form may assume the shape of fine needle-like crystals which are actually pseudomorphs after gold amalgam.

- 3. Prepare a parting solution by diluting commercial nitric acid with water to a strength which will dissolve mercury without violent action. A 1:1 dilution is usually satisfactory.

- 4. Large-volume or hard-packing black sands that are difficult or tedious to pan may be amalgamated in a glass jar rotated about its longitudinal axis at a peripheral speed of 500 inches per minute. The addition of a small amount of lye will counteract oil or grease and will generally assist amalgamation.

- 5. The described procedure will extract all free gold recoverable by commerical placer methods. With care, extremely low gold values can be determined. Where so-called "rusty" or coated gold is present, provisions should be made to scour or otherwise brighten the gold prior to amalgamation. This may he done by rubbing it on the bottom of the pan or adding a few pebbles to the amalgamating jar. Fine grinding or pulverizing should be avoided.

REFERENCES CITED (PART V)

Gardner, E. D. and Allsman, Paul T., 1938, Power-shovel and dragline placer mining: U.S. Bureau of Mines Information Circular 7013, 1938.

Janin, Charles, 1918, Gold dredging in the United States: U.S. Bureau of Mines Bulletin 127,1918.

Mertie, John B. Jr., 1954, The gold pan; a neglected geologic tool: Econ. Geology, Vol. 49, No.6, Sept. - Oct., 1954, pp. 639-651.

Theobald, Paul K. Jr., 1957, The gold pan as a quantitative geologic tool: U.S. Geol. Survey Bull. 1071-A, 1957.

Vanderburg, William 0., 1936, Placer mining in Nevada: University of Nevada Bull. Vol 30, No.4, May 15, 1936.