About Some of The Mines

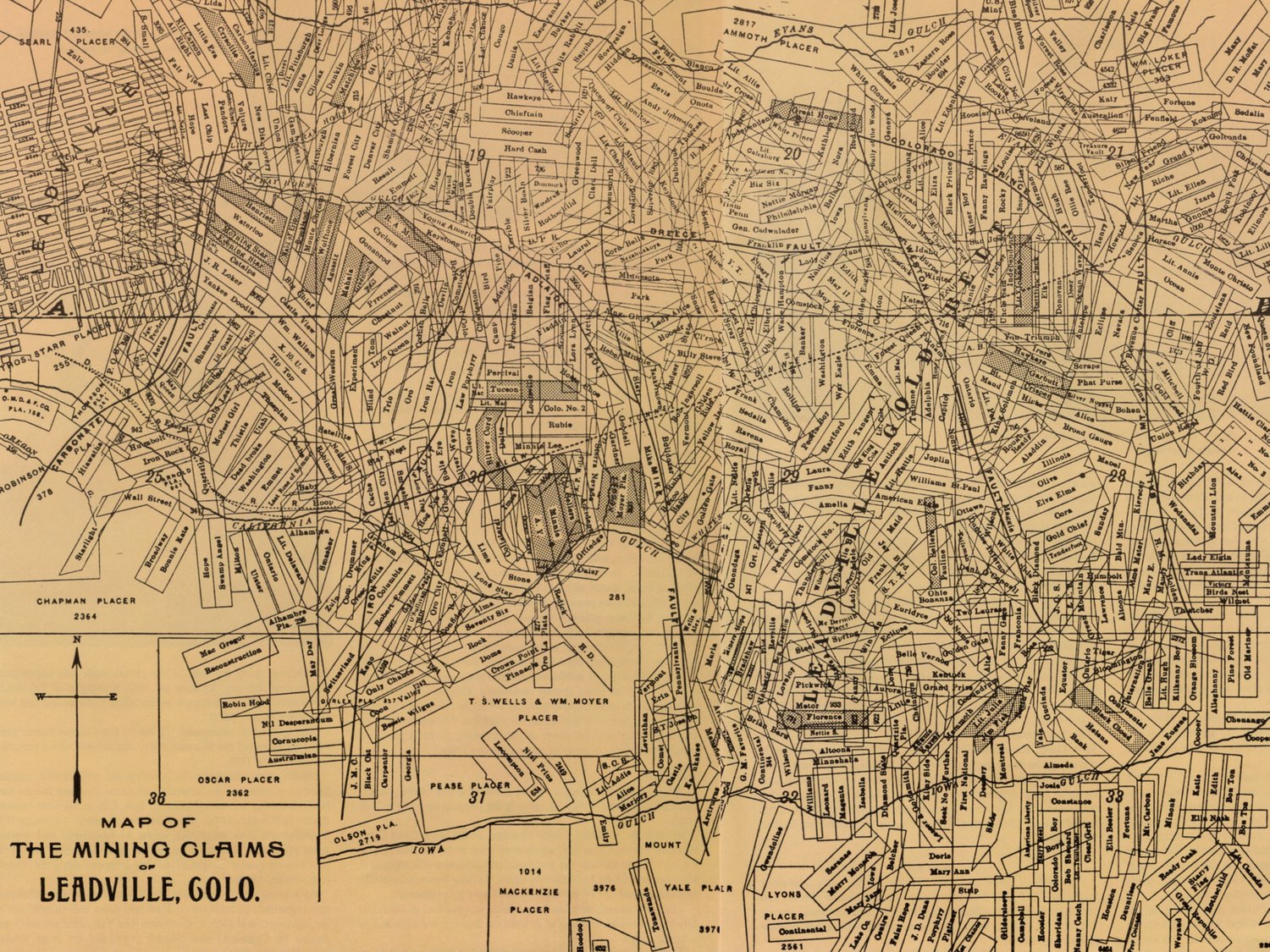

Considering that the Leadville area encompasses nearly 2000 mines, it would be impractical to discuss them all here. The following discussion touches upon some of the more interesting claims, with the understanding that there are many more stories left untold.

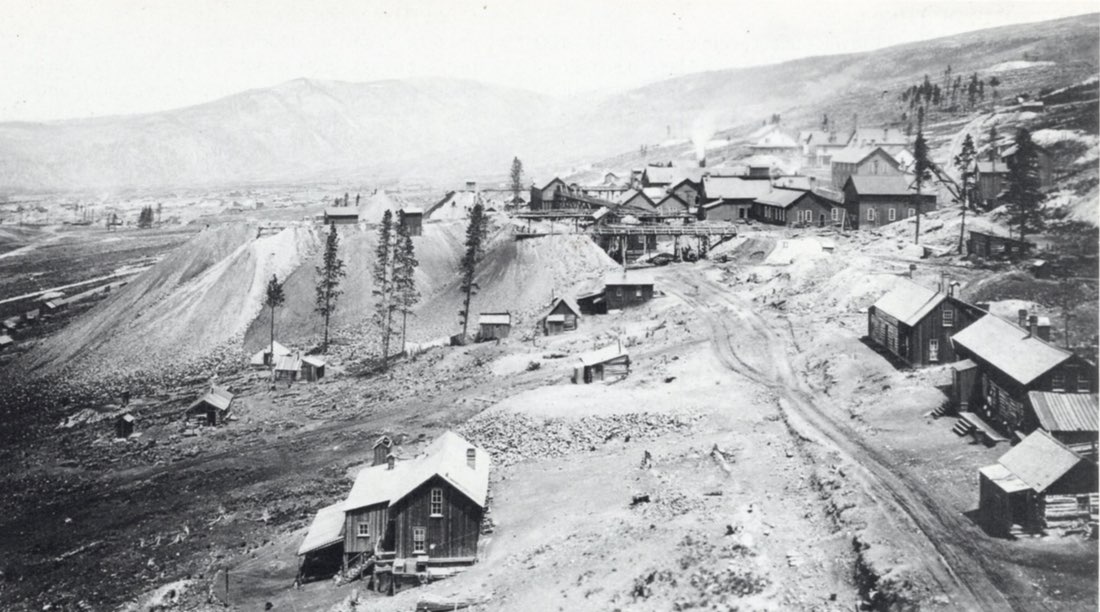

PRINTER BOY HILL

Printer Boy Hill Printer Boy Hill lies at the southernmost extension of the so-called Leadville gold belt. In this area gold mineralization seems to be closely related to bismuth mineralization (Loughlin and Behre, 1934, 1937). Both sulfide replacement and vein deposits occur in the area.

Printer Boy Mine

Locating specific information on many of the earliest mines is always extremely difficult, owing to the fact that no one at the time was especially interested in preserving for posterity any accounts of what actually happened. All energies were turned to producing precious metals and earning money, rather than to writing and recording.

Hardly any mine has presented such a challenge in research as the Printer Boy. Some few sources place its location in 1861 (Manning, 1895), while most say the date was 1868. Its low claim number certainly suggests the earlier date.

While it is true that the first discovery of gold in place was made at the Printer Boy in June, 1868, on the north side of Georgia Gulch by Messrs. Smith and Mullen, research suggests that it had been a claim long before that time and had been neglected for a while.

One source says that for a year very little attention was paid to the claim by anyone, and during the absence of the owners the claim was jumped and several thousand dollars in ore taken out. Attention of the owners was attracted and litigation ensued, bringing about the notice of the public (Raymond, 1872).

Since this mine, along with the Antioch, was opened to try to locate the source of the California Gulch gold, it appears odd that it would have been ignored for a while. If this occurred before 1868, however, when the lode was discovered, it surely might have taken place.

The notes of S. A. Safford, Surveyor, dated June 9, 1868, state that the claim contains “veins of ore from three to eighteen inches wide, composed of decomposed quartz containing some copper and very rich in free gold. The crevice usually carries a vein of dark gray cleavable talc on the west wall. Twenty-six ounces of gold have been taken from one pan of selected ore from this lode." It was “worked by shafts and hand windlass, also by a tunnel” and the ore assayed at $75 per ton. At that time there was no mill (Bureau of Land Management files).

Eventually the float of yellow iron-stained clay was followed (after 1868) until it turned down into the formation in place, which proved to be the vein. A shaft was then sunk and discovery was made of a large body of ore. The vein was only about 50 cm wide and the ore consisted of decomposed porphyry, clay and iron, in walls of pyritiferous porphyry (Emmons, 1886; Lakes, 1895).

In 1880, Dill (1881) described the workings as primitive, unsafe and haphazard.

Ingham (1880) states that the claim proved to be valuable enough that a stamp mill was erected to crush its ore, and that the mill produced about $250,000 in bullion from 1868 until 1874. He also says that the mill “was not very successfully managed thereafter." Monograph 12 asserts that the Printer Boy "produced a large amount of gold between 1866 and 1870, of which no record can be obtained” (Emmons, 1886).

Operated by the imperfect methods of that early period of mining, the Printer Boy produced, in the course of time, some extraordinary returns because the rich pockets lay comparatively near the surface (Hall, 1890; Griswold, 1951).

“Large bodies of decomposed quartz, soft and porous, were found, carrying great masses of free gold in nuggets, bunches of fantastically formed and matted wires, and beautiful crystallizations. Many large glass jars, such as are seen upon the shelves of drug-stores, were filled with these remarkable specimens, and exhibited, first at the national banks in Denver, and subsequently in Philadelphia and New York, where they excited much admiration, and for a time, revived the interest of speculators in the mines of Colorado” (Hall, 1890).

The Pilot fault divides Printer Boy Hill into two parts, and J. Marshall Paul is said to have made a fortune from the mine before finally selling the north half in 1868. Since that time it has been known as the Upper and Lower Printer Boy (Dill, 1881; Lakes, 1895).

Circa 1893, after sinking a shaft, running two drifts, and mining over $100,000 in value, a second shaft was started on the property. It was in this second shaft that two ore veins were found. From one of these “$4500 in gold nuggets were panned out from a single pan of dirt” (Dill, 1881); $4500 in gold computes to approximately 20 pounds troy of gold in a single pan, or about $74,000 at late 1984 prices! Nuggets of large size were taken from the mine, many exceeding 5 ounces, and one of 28 ounces (Dill, 1881).

“In the deeper workings considerable iron and copper pyrites and some galena and tennantite were found. Gold occurred in both pyrite and galena, and a piece of ore containing galena crystals, connected by a filament of wire gold, was one of the show specimens at the mine. Selected specimens are said to have contained 122 ounces of gold to the ton, and the average assay is given at three to four ounces” (Emmons, 1886).

In view of all the reports of fabulous finds, quite an exhaustive search has been conducted to locate specimens from the Printer Boy mine. To date no well-documented gold specimens have been found, after consulting the Harvard Mineralogical Museum, the Philadelphia Academy of Natural Sciences, the Smithsonian Institution, the Los Angeles County Museum of Natural History, the Denver Museum of Natural History, the Geology Museum at Colorado School of Mines and numerous private collectors. This leaves it open to conjecture as to whether or not the lavish reports were just a promotional scheme designed to encourage investment.

Lillian Mine

The Lilian mine carries one of Leadville's most unusual mineral assemblages, in a sulfide replacement body. The mine is the discredited type locality for lillianite. But, in one of those peculiar twists of mineralogical history, even though the type specimens were discredited as mixtures, the species has remained valid. By coincidence, material matching the originally described (though erroneous) composition was subsequently found at the Sultan mine, Silverton district, Colorado, and in the White Cross-Hurricane Basin district, Colorado, so the species has been allowed to stand. The original author (Keller, 1889) therefore has the unique distinction of having described and named a valid species which he had never seen, at a time prior to its discovery.

CALIFORNIA GULCH

Rock Hill and Iron Hill are here included in the California Gulch area. Orebodies begin on Iron Hill, to the north, and pass under California Gulch to Rock Hill, on the south (Loughlin and Behre, 1947). The upper portions of California Gulch intersect the goldpyrite vein deposits radiating from Breece Hill and Printer Boy Hill. These were the veins which furnished most of the placer gold found in California Gulch in the early boom days.

The gulch is also the scene of the discovery of bonanza-grade silver-lead replacement bodies in limestone, where cerussite and chlorargyrite were the main ore minerals.

Many well-known mines from this area probably produced fine specimens, but the early-day Leadville mineral specimens have had a low survival rate. The best-known specimen producers include the Tucson mine, Moyer mine, and the A. Y. and Minnie mine.

Tuscon Mine

It seems very likely that the Tucson mine, patented in 1886 by Charles J. Doud et al. (Bureau of Land Management files) was one of the claims purchased by Stevens and Wood as they developed the carbonates on Iron Hill. The Tucson, along with the Luella, was added to the Iron Silver Mining Company of W. H. Stevens and Levi Z. Leiter in 1881, Leiter having purchased Wood's interest (Dill, 1881; Ebbley, 1949; Blair, 1980).

In any event, the first operations were through the north and south incline by Stevens and Leiter, and the Tucson shaft was sunk to a depth of 338 meters (1,100 feet). At that time it was recognized as the best in the Leadville district (Ebbley, 1949).

In 1910 high-grade silver, one assay being as high as 2,000 ounces per ton, was mined in the lower levels. Considerable mining was carried on from 1912 to 1918, at which time lead and zinc sulfides were the main ores. A few attempts to reopen the mine between 1918 and 1926 were reported, but none was successful, and the property remained inactive until 1940 (Ebbley, 1949).

In that year the upper portion of the shaft was reopened by Axel Lind and Associates to gain access to a zinc carbonate (smithsonite) orebody known to have been left partly unmined by former operators. Production was discontinued after making five shipments of ore, because the minimum grade acceptable to the buyers was raised to 30% zinc. Low-grade lead carbonate (cerussite) ore was mined by the lessees and shipped to the local smelter until the mine was closed again in 1944 (Ebbley, 1949).

The upper workings of the Tucson mine intersect oxidized lead-silver ores in the Leadville limestone. A large specimen of jackstraw cerussite in the Colorado School of Mines collection is from this zone.

Many fine specimens have come from the Tucson mine. Chapman (1941) reports gold with hessite, altaite and galenobismutite. A material called “schapbachite" was found to be a mixture of hessite, bismuth-bearing altaite and gold; it occurred as a coating on 2.5-cm galena crystals.

A specimen of flattened galena crystals, apparently twinned on the spinel law, exists (ER collection); the crystals have a drusy gray coating (“schapbachite”?) and are associated with sphalerite and pyrite.

Fine, large, pyritohedral to octahedral masses of pyrite crystals have come from the Tucson mine, as well as siderite and botryoidal hemimorphite.

Vugs of twinned sphalerite crystals, some of which reached diameters of more than 1.2 cm and small well-developed crystals of arsenopyrite have also been reported (Emmons et al., 1927).

"An unusual occurrence of drusy and stalactitic galena was noted on the sixth level of the Tucson mine. This galena had grown upon zincblende crystals in vugs in sulfide ore along the hanging wall of the Tucson fault. The stalactites were as much as half an inch in length and were distinctly later than the blende or the few crystals of chalcopyrite that accompanied it. The galena was coated with a dusty film that may have been argentite, as the ore at this place assayed 80 ounces to the ton in silver” (Emmons et al., 1927).

Much of the sulfide material is associated with flattened rhombs of siderite.

Moyer Mine

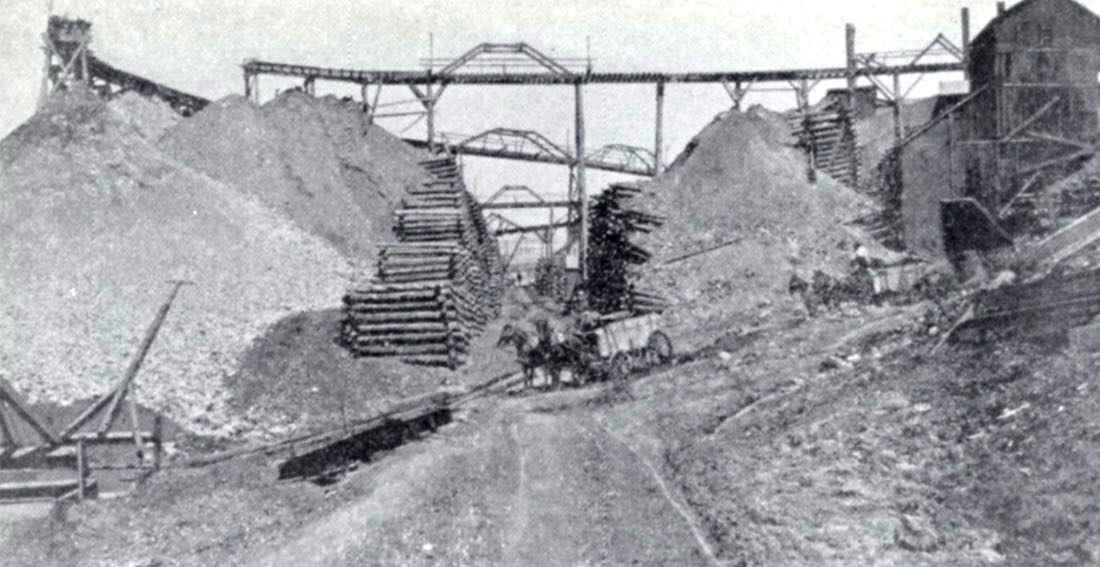

Patent was granted on January 30, 1880, to William Moyer and Judge Wells for the Moyer placer, which they had located in 1877, under a special Act of Congress passed in 1872. Although it straddled California Gulch, it also extended up the south slope of Iron Hill (Silversparre, 1882; Denver Tribune, 1899 and 1902; newspaper, name unknown, 1888).

On February 24, 1880, the upper or northern portion was sold to Stevens and Leiter as part of the Iron Silver Mining Company and holdings grew steadily under several different managers.

The Report of the Director of the Mint tells of a new strike reported in 1882. “Near the porphyry, or top of the orebody, the mineral is a fair galena ore, carrying some sulphate of lead, and only small quantities of iron pyrites and zinc blende” (Burchard, 1884).

In 1890 some 2.5 km of drifts had been run in the Moyer alone (Harper, 1890). This included two shafts: the lower or south shaft sunk in 1882 (described in the above-mentioned Mint Report) and the north shaft, sunk sometime later approximately 800 meters to the north.

The Moyer mine shipped the first zinc to Belgium via Galveston, Texas, in 1899 (Blair, 1980) and thus in its own way was responsible for some of the beginnings of one of the later periods of Leadville – that of the lead-zinc-silver-gold, or composite, era.

Aside from good ore, the Moyer's primary claim to fame is the multitude of ghosts which are said to inhabit it. Senator Gallagher of Silver Plume, who was killed in the mine, is said to have been seen wandering around, and the disembodied souls of twelve workers crushed to death in a cave-in have continued to occupy it (Blair, 1980).

The main ore shoot, a blanket-shaped sulfide orebody, measured 28 meters thick and 150 x 600 meters across (Emmons et al., 1927). Some of the Moyer orebodies were pure, solid pyrite which was ultimately mined as flux for the Leadville smelters. These orebodies were usually replaced limestone blocks completely surrounding intrusive porphyry. In places alternating bands of pyrite and sphalerite appear to have preserved original bedding structure. Another Moyer orebody was composed of mixed sulfides thoroughly shot through with secondary cerussite and limonite (Emmons et al., 1927).

The Moyer has produced lustrous, black, 2.5-cm sphalerite crystals on pyrite matrix (Henderson, 1926; Kosnar, 1976); hemimorphite; some very nice, although small (1.2-cm) modified crystals of galena; and some beautiful pyrite specimens showing combinations of the octahedron and pyritohedron (ER collection).

CARBONATE HILL

Carbonate Hill lies between the Pendery fault on the west and the Iron fault on the east. The Tucson-Maid reverse fault passes through the hill and appears to have been a factor in the development of sulfide replacement orebodies at the Wolftone mine.

The mines on Carbonate Hill were the second major group developed on secondary lead-silver bonanza deposits in the early days. As in the California Gulch area, the orebodies occur mainly in the upper Leadville limestone. Just below and sometimes adjacent to these orebodies lay the oxidized zinc ores for which the area is best known; these were not considered economical in the early days of mining and were temporarily bypassed.

Common botryoidal smithsonite was reported from the Maid of Erin mine (Loughlin, 1918), and other mines in the area reported fine smithsonite druses and mixtures with iron and manganese oxides. When the district finally did begin to produce zinc, the result was significant: $43,000,000 worth from 1910 to 1916, most of it from Carbonate Hill.

Wolftone Mine/A. M. W. Properties

The Wolftone mine, named for Theobald Wolfe Tone, the spiritual father of modern Irish nationalism, was located in 1876 by Samuel Morgan and Aden Alexander. Situated on Carbonate Hill, California district, 1.6 km (1 mile) from Leadville, five shafts were sunk ranging from 9 to 25 meters in depth and the ore was said to have a value of $250 per ton (Corbett, 1879).

Malta Smelting and Mining Company was the claimant requesting a survey in 1880; patent was granted later that year (Bureau of Land Management files).

“At a depth of 633 feet ore was first struck, and a body of iron pyrites, mixed with galena, passed through, which is 7 feet in thickness. It is not similar to other ores found on the hill, and is believed by those who have examined it to be an overlying iron body, and that the regular ore contact is at a still greater depth. ... The strike is one of the most valuable ones made about Leadville for a year past, and will add large territory to the productive mines of this camp” (Burchard, 1882).

The A. M. W. Company, made up of the Adams, Maid of Erin and Wolftone mines, was organized sometime prior to 1892. The President and General Manager of the A. M. W. was S. D. Nicholson (Blair, 1980; Holmes, 1983).

When in 1910 the first highgrade zinc ore, reported as calamine (hemimorphite), was discovered in the May Queen mine, Nicholson began a search for oxidized zinc ores in the old workings of the Wolftone and discovered the largest body of zinc silicate in the district (Loughlin, 1918).

In 1913 Nicholson sent an unidentified sample of zinc ore to the Colorado School of Mines, where G. M. Butler identified it as a zinc-rich variety of aragonite and named it nicholsonite after the man who had brought it to his attention (Loughlin, 1918).

As the development of the oxidized zinc ores intensified, what was believed to be another new mineral species was found in the Wolftone and named wolftonite, but further study suggested it to be hetaerolite. In 1913 Ford and Bradley described it as a rare vugfilling mineral, found with a radiating mammillary structure, whose outer surfaces were generally smooth and rounded. More chemical analysis showed a quantity of water in the formula, indicating the mineral was actually hydrohetaerolite.

In 1920 the Wolftone mine had been developed by a shaft 1,120 feet deep, from which eight leads had been driven” (Hornor, 1920).

The Wolftone had produced hemimorphite, galena, sphalerite, and the other minerals already mentioned. Emmons et al. (1927) also reports “a considerable quantity of pyrite ... with radiating structure suggestive of marcasite, but chemical tests proved it to be pyrite. The surfaces of many of the radiating pyrite crystals are coated with pyrite crystals of more ordinary form.”

Yak Tunnel

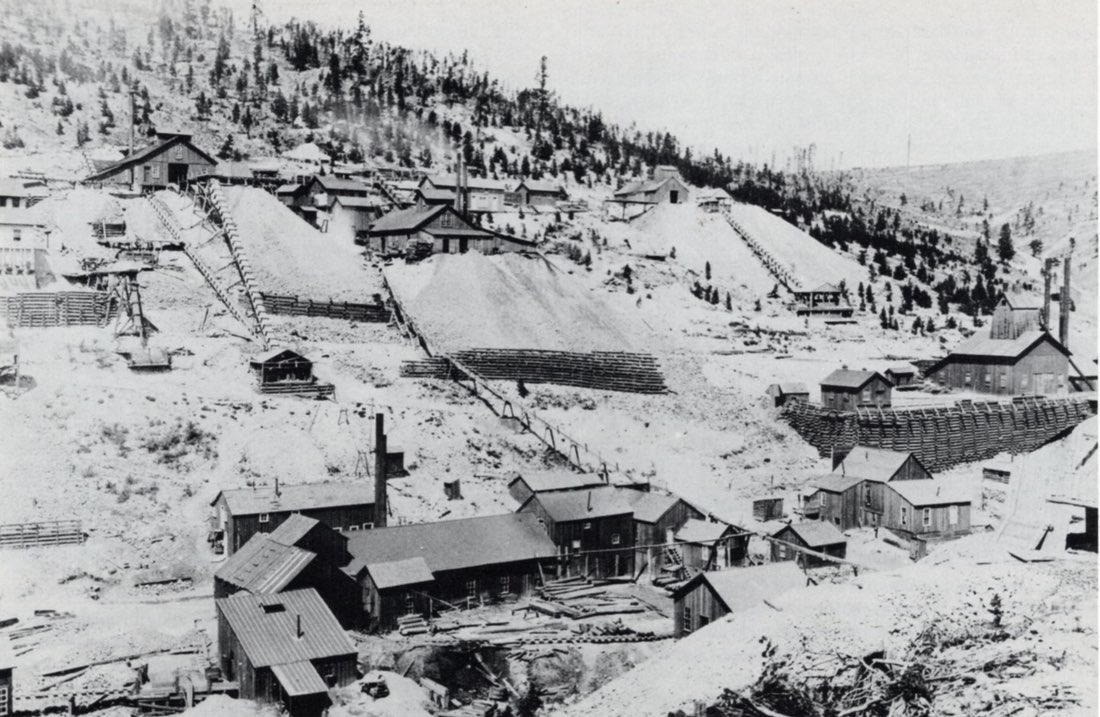

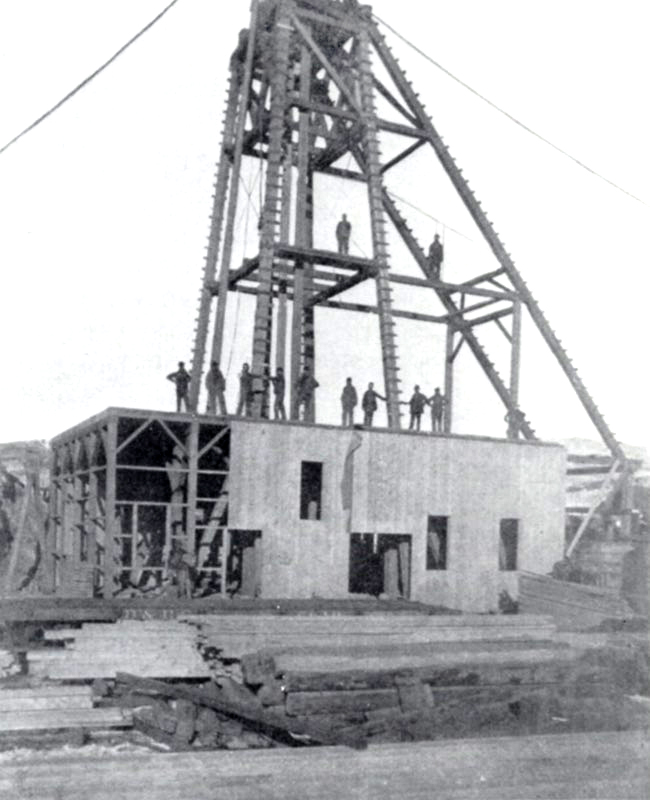

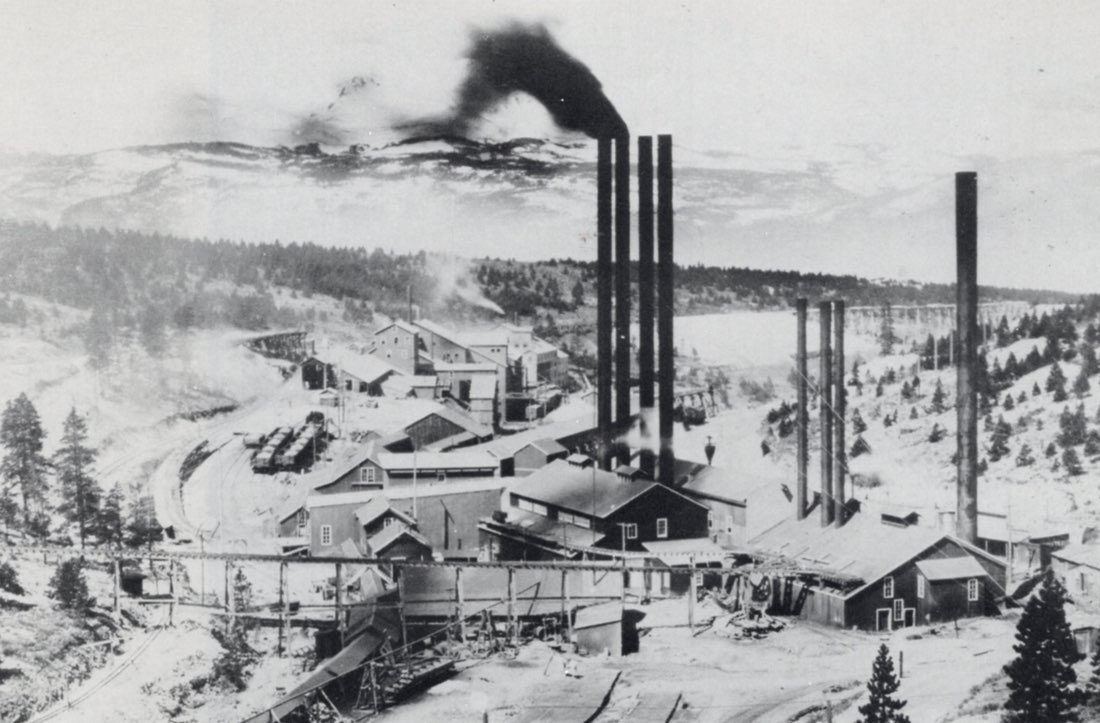

What has been and might still be considered one of the greatest undertakings in the Leadville camp is the development of the Yak tunnel.

In 1899, A. A. Blow, general manager of the Silver Cord Combination Mining Company, was instrumental in the construction of a tunnel. Its portal is on the south side of Carbonate Hill, about 1.2 km southeast of the Leadville city limits, halfway between Leadville and the former site of the most recent Oro City settlement.

The Blow tunnel, as it was first called, was planned to reach the Silver Cord incline and was to be used for draining the mine and as a haulage-way. Human power was the force behind the first haulage, but when the distance from the face to the portal made this impractical, mules came into use. By June 24, 1892, a distance of 910 meters (2956 feet) to the Imes station of the Silver Cord incline had been completed (Luke, 1971).

The tunnel had penetrated 1.2 km to the Colonel Sellers mine when the repeal of the Sherman Silver Act brought about cessation of the work in 1893.

Shortly after shutdown the two-year-old mill burned, causing Blow to recommend the formation of a new company for the purpose of driving the tunnel through Iron Hill to the area beneath Breece Hill (Luke, 1971). It was felt that the mines on Breece Hill, including the Ibex properties, could be unwatered and worked more effectively through a tunnel. In addition, there would no doubt be exposed a number of exciting prospects along the tunnel's route (Blair, 1980).

As a result, the Yak Mining, Milling and Tunneling Company was organized. In addition to Blow and other individuals, one of the organizers was John F. Campion. The Yak name probably was chosen by Campion, who named properties for large hoofed animals (Luke, 1971).

Work on the new project began in March, 1895, and by the end of 1899 the tunnel had been driven 2.5 km to a depth of 400 meters below the Forest Queen on Breece Hill (Luke, 1971).

At the turn of the century attention shifted from gold and silver to increasing amounts of lead-zinc ore, with over 1000 tons per year being shipped by way of the Yak. It was at this time that consideration was given to continuing the tunnel under the Mosquito Range and emerging into Park County (Luke, 1971). However, this plan never came to fruition.

The Yak workings reached the Resurrection #1 mine in 1908. By January 1, 1909, it extended 4.8 km into the hills, and October 30 of that year saw the Resurrection #2 included in the networks of laterals, shafts and raises. During this time the work continued to the accompaniment of numerous improvements, including electric locomotives, a new electric generating plant and a new magnetic separator mill (Luke, 1971).

The terminus of the Yak was reached in October of 1912, approximately 6.4 km (4 miles) from daylight, "in the vicinity of the Diamond and Vega properties, approximately one mile northwest of Little Ellen Hill” (Luke, 1971).

Mines all along the route of the Yak were unwatered, a benefit for which owners paid the Yak Mining, Milling and Tunnel Company. “Many of the mines along the route were worked through the tunnel and for that privilege they also paid. The Company owned a considerable number of claims outright; others they leased and paid royalty on; still others were held in ‘perpetual contract,' which gave the Yak an easement through the property and allowed the owner to work his own mine if he desired” (Blair, 1980). Of course, there were fees and royalties charged for this privilege, also.

In 1917 ASARCO purchased an undivided half interest in the Yak, but activity slowed drastically after World War I and through the depression of the 1930s. Abandoned workings filled with water; some have never been pumped dry. In 1938 Newmont Mining Corporation and Hecla Mining Company purchased interests and joined ASARCO in the Resurrection Mining Company, which included the Yak properties (Luke, 1971).

Production flourished during World War II, but slowed considerably afterward. A fire in 1956 destroyed most of the surface facilities of the Resurrection, resulting in a mine shut-down in 1957. ASARCO's smelter closed in 1961, and in 1963 the tracks to the portal of the Yak were removed.

The Yak tunnel provided its owners with a steady income for nearly half a century, and it was still a part of local mining operations in 1980. It enabled several marginal properties to operate profitably by lowering overhead costs; it provided drainage, transportation and ventilation to numerous mines; it extended the growth and production of the Leadville district for many years (Blair, 1980). By 1971, only the Black Cloud mine (ASARCO) maintained access to the Yak; all other operations had ceased.

It is difficult to say for certain where mineral specimens marked “The Yak” came from. Specimens could have originated in the Silver Cord, which consisted of “vuggy veinlets of pyrite and quartz cementing the quartzite fragments and partly replacing them, practically pure pyrite to practically pure zinc blends (or sphalerite), and barite in small crystals” (Emmons et al., 1927). They might also have come from any of the mines worked through the 6.4 km of the tunnel system. Well-formed galena crystals have also been labeled “The Yak."