Photo Description

On this bluff in the late 1800's the highest underground mine in the Cripple Creek Mining District was collared in at an elevation of about 10,750 feet above sea level. In 1895 William S. Stratton purchased the operations and worked them under the Stratton Cripple Creek Mining and Development Company. Also at this site is the remnant of the blacksmiths forge building used at this mine.

The American Eagles Mine involved three shafts and the workings were further connected to adjoining properties. The underground workings reached 1,540 feet below you by 1902, making it the deepest shaft in its time. The workings progressed deeper, but production and shipping of ore was sporadic until 1936 when a rich strike was made between the 19th and 21st levels (1900 and 2100 feet below you). The mine produced ore worth at that time $7 per pound.

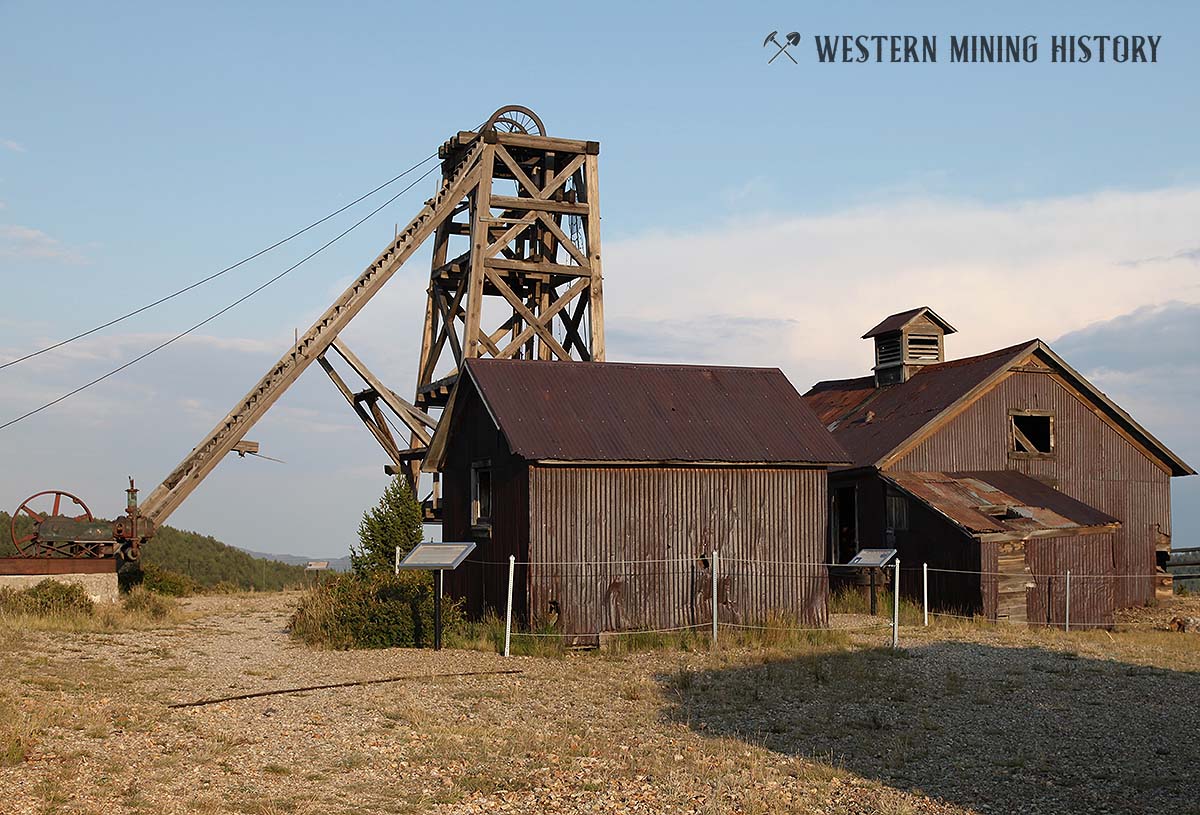

Headframes sit above the vertical shaft in order to support the sheave wheel or pulley system that passed the hoist cable from the steam- or electric- powered hoisting mechanism to the metal cage that hauled workers and equipment down into the workings and ore and workers out to the mine. At this site a Stearns Rogers Company double-drum hoist, still in place north of the headframe, did the job. The 750 hp hoist was powered by steam, which was generated in coal-fired boilers using water supplied by the Altman Water Company. Workers were lowered into the the workings and brought up at shift changes. Ore would be raised and supplies lowered between the shift changes. The Mollie Kathleen Gold Mine Tour near Cripple Creek offers a chance to experience this unique trip to work. Double-drum hoists allowed the use of two cages, or platforms, one rising and one lowering simultaneously. Examples of other hoists, cables and flat ropes may be viewed at the Victor Lowell Thomas Museum as well as the Independence Mine and Millsite Trailheads.

The wooden headframe, while generally characteristic of headframes in the District, provided an example of a more unique feature - that of detaching hooks. These hooks were designed to release the main cage should the hoistman overwind the hoist cable so that the man cage would rise up toward the sheave causing injury to miners.

From a sign at the site