The remains of mining-era arrastras are fairly common in the West, but what exactly are they? The short answer is that the arrastra was the most primitive method used to crush ore into a fine enough powder that the precious metals could be separated from the host rock.

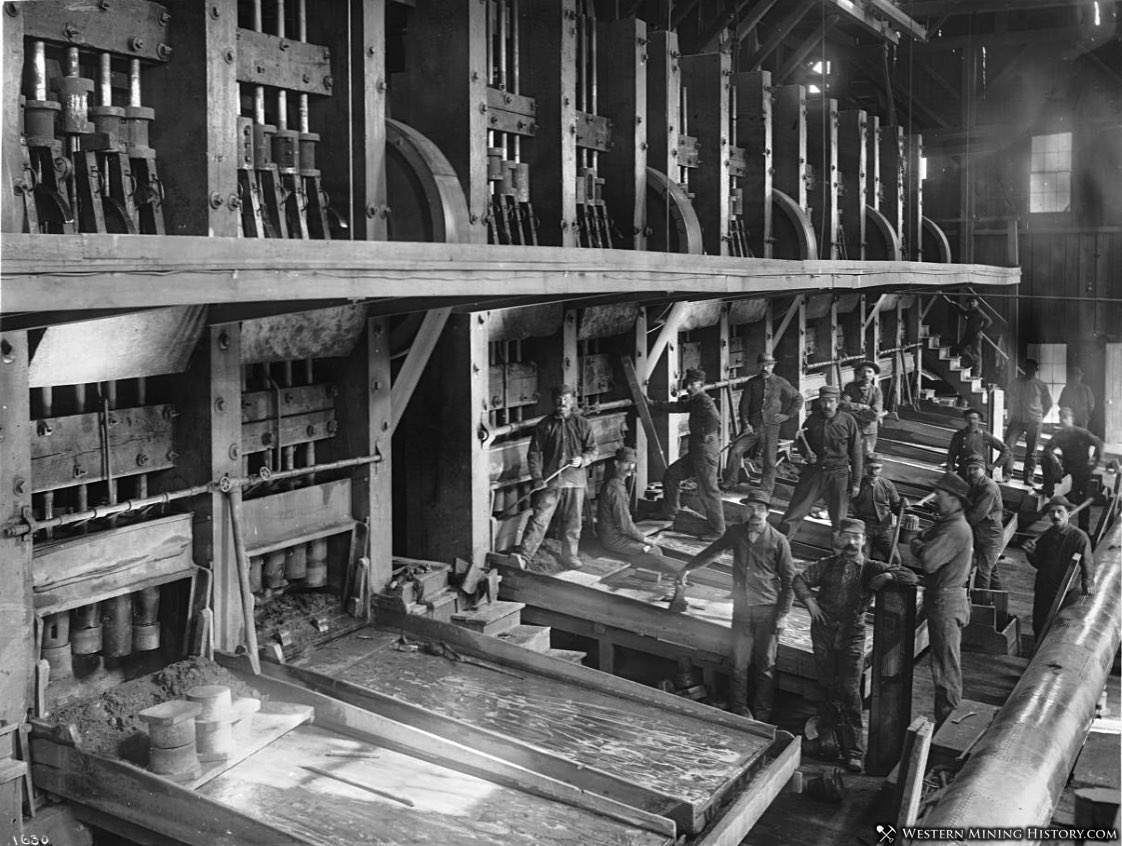

While many people are familiar with the simple and crude version of the arrastra, it is also true that the arrastra method evolved into much more elaborate arrastra mills that were often housed in a building and powered by water from flumes or even steam power.

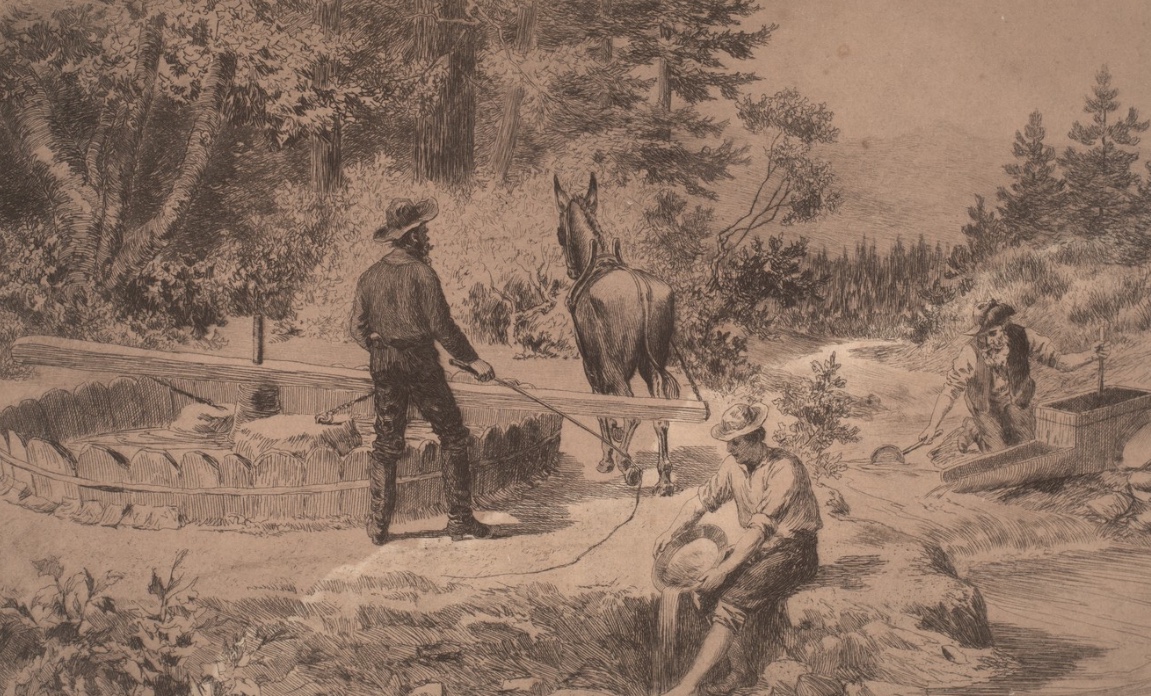

The Mexican arrastra (also “rastra” or “arastra”) was the earliest type used during the California Gold Rush in the 1850s. Simply constructed, these devices consisted of a flat track of stone inside a low wall of rock or wood forming a basin to hold the ore, and center post and horizontal shaft made of wood (often just a small tree trunks).

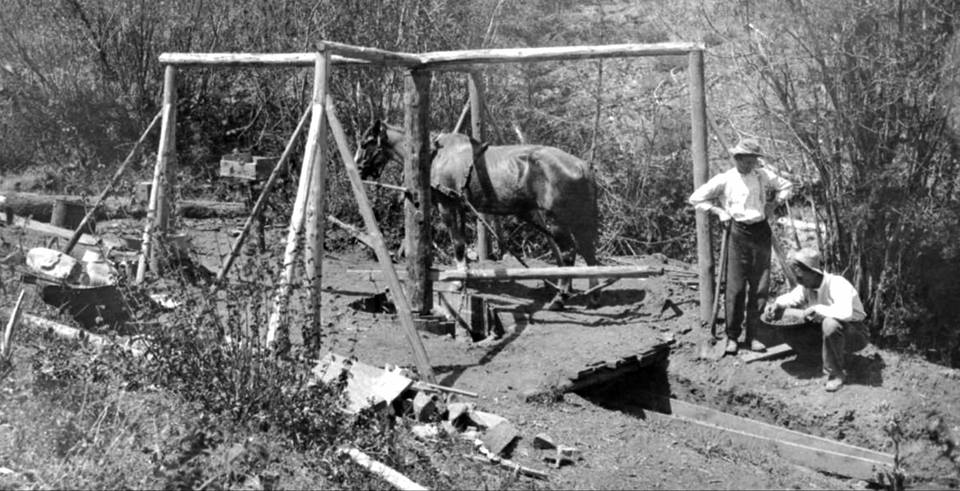

Powered by horse or mule, the shaft would drag one or more large stones in a circular path on top of the flat stone base, crushing the ore that has been placed in the basin. Mercury would have been added to the ore to help capture the gold as it was separate from the pulverized rock.

Although simple in design, the Mexican style arrastras saw use for over 50 years. The ease of which they were built and operated made them ideally suited to small mining operations. The photo below shows an arrastra being used on Jackson Creek – Jackson County, Oregon in 1909, testament to the enduring usefulness of this simple device.

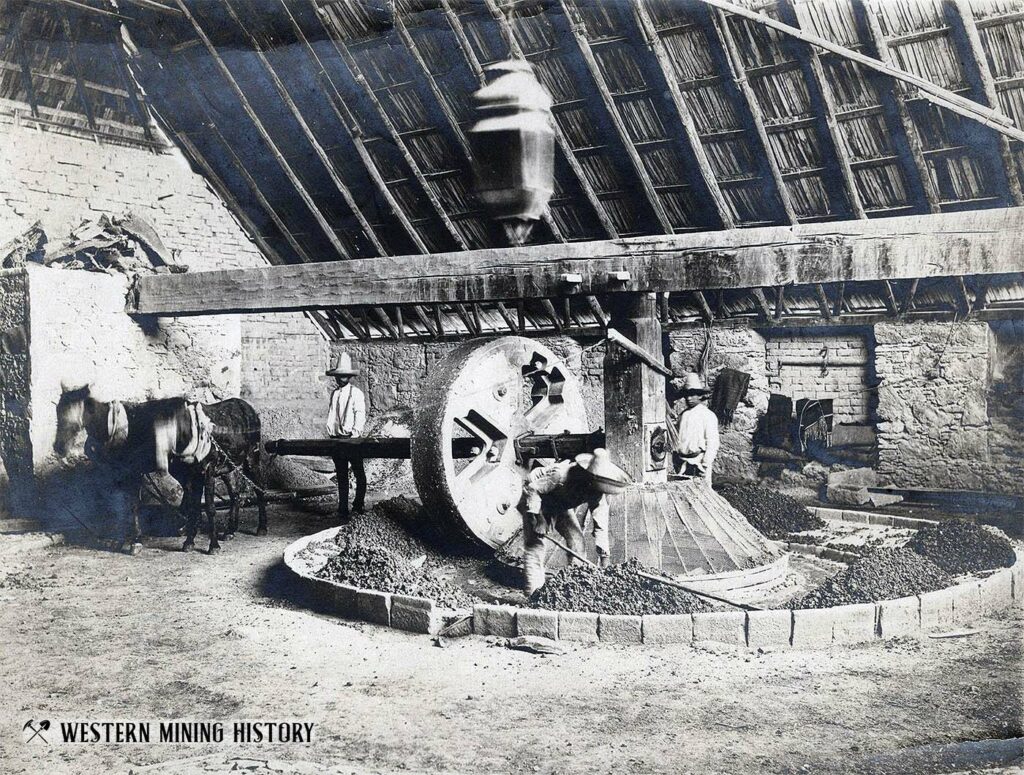

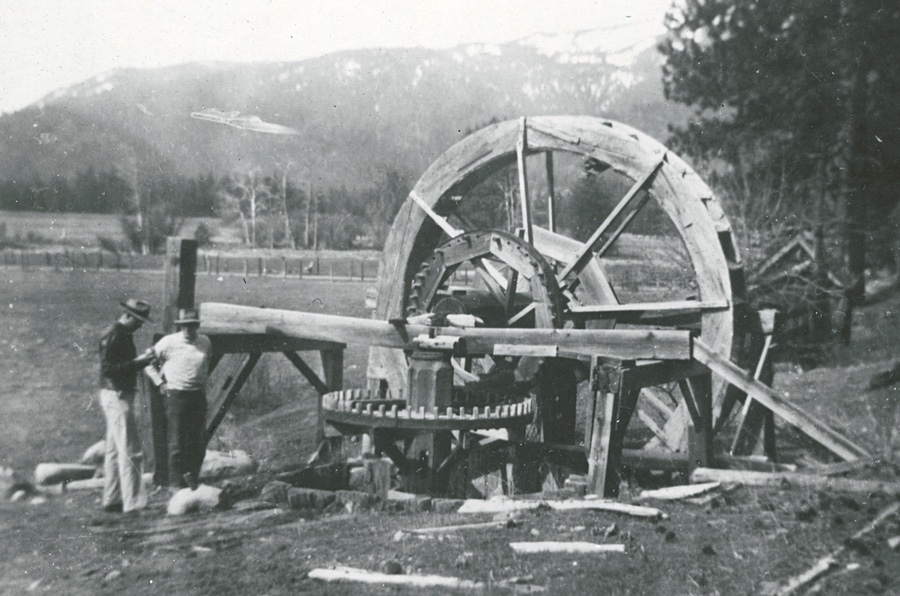

A more elaborately built form of the Arrastra was the “Chilean Mill”, a design that was brought to North America by Chilean miners during the gold rush. These mills were heavily built, powered by mules or horses, and featured a heavy stone that rolled over the ore rather than being dragged.

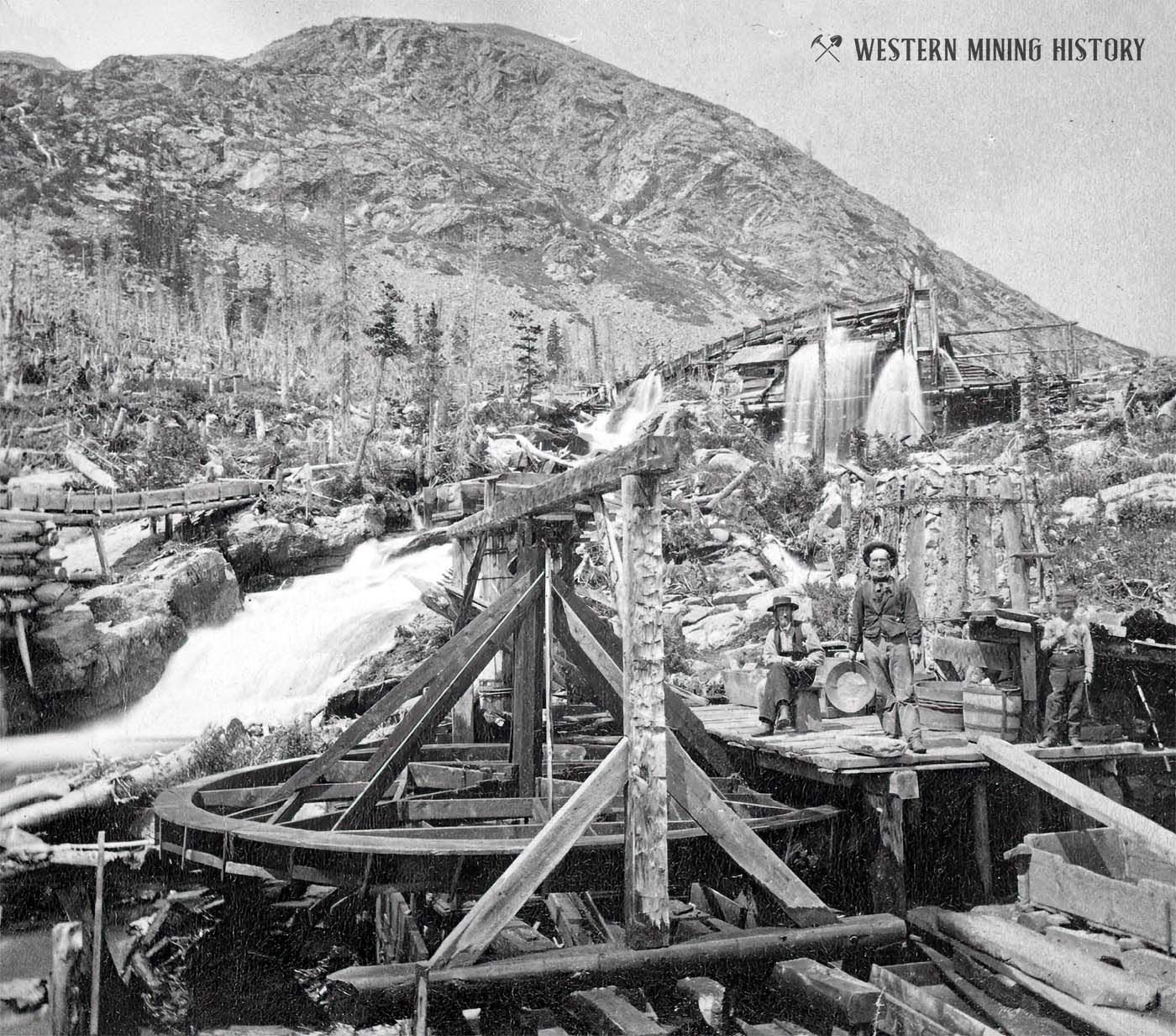

Mining technology evolved rapidly in the West and the simple Mexican arrastra was improved and customized for many different applications. When water was plentiful, flumes and water wheels were often used instead of pack animals to power the arrastra.

The elaborate workings depicted in the above 1860s photo from Montgomery, Colorado illustrate how it wasn’t long before the arrastra was incorporated into much more complex mining operations. The arrastra pictured seems to show a horizontal water wheel. While photos of this type are rare, the design is mentioned in mining journals from the 1800s.

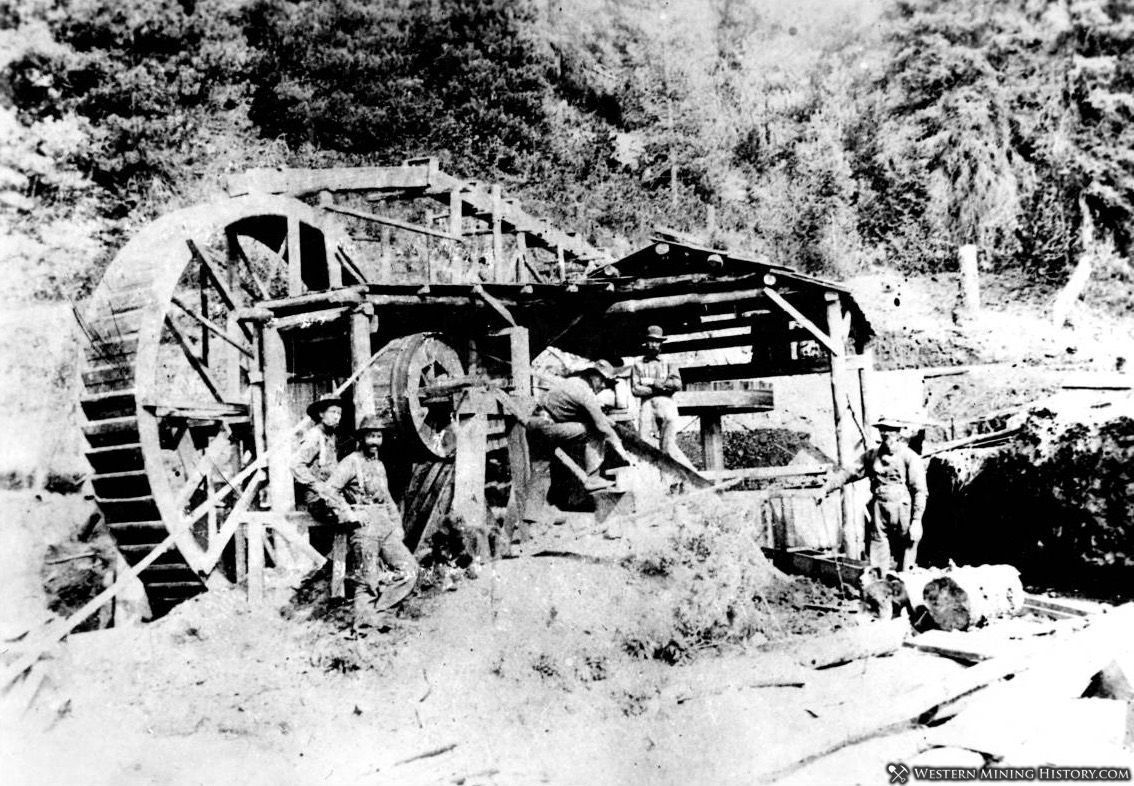

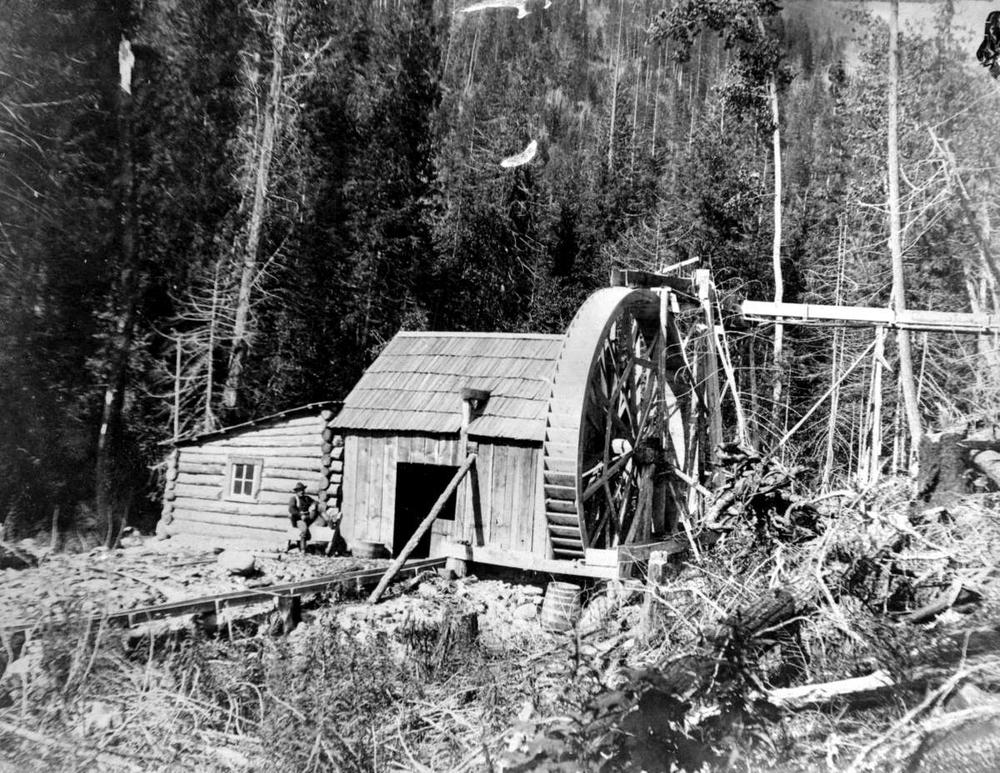

Above and below are photos from Pierce, Idaho, and Dixie, Idaho show more common water-powered arrastras with vertical water wheels.

The arrastra method of crushing gold-bearing rock was in some cases superior to more modern stamp mills of the late 1800s. An 1883 report from the California Journal of Mines and Geology states that the gold-bearing cemented gravels in Yuba and Nevada counties were being processed by steam powered arrastras:

“Advantages of this process consist in the low first cost of the plant, in its simplicity and that of its mechanical devices, in the extreme cheapness of the cost of treatment, and in the apparent effectiveness of the process itself…… The cost of milling in arrastras under proper conditions is 6 to 8 cents per ton; by stamp this would be 25 to 40 cents per ton.”

Arrastras remained popular throughout the 1800’s, and even into the early 1900s for smaller operations. Today remains of Arrastras can be found in many locations throughout the West.

At a few locations, complete or replica arrastras are sometimes operated to demonstrate how the arrastras worked. Liberty, Washington has a Mexican-style arrastra and South Pass City, Wyoming has a replica of a water powered arrastra.

Arrastras were an important and popular technology in the development of Western mines. Fortunately, enough photos and physical evidence remains to adequately document these fascinating machines.

Winning the Metal: Ore Mills of the West

Arrastras were replaced by much larger and more complex milling methods and machinery. Winning the Metal: Ore Mills of the West takes a look at some of the more common mill processes and includes numerous photos of the West’s great mills.